Pins, Connection Plates, and Centre Disks

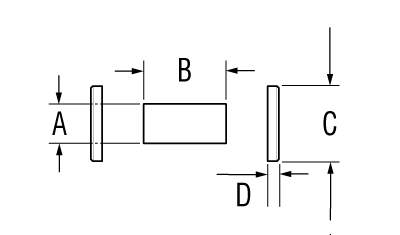

Standard Pin Sets

|

|

A | B | C | D |

|

|

in. | in. | in. | in. |

|

M12

|

0.47 | 0.95 | 0.79 | 0.12 |

|

M16

|

0.63 | 1.10 | 0.99 | 0.20 |

|

M20

|

0.79 | 1.42 | 1.26 | 0.24 |

|

M24

|

0.95 | 1.69 | 1.38 | 0.24 |

|

M30

|

1.18 | 2.09 | 1.97 | 0.39 |

|

M36

|

1.42 | 2.56 | 2.17 | 0.39 |

|

M42

|

1.65 | 2.96 | 2.36 | 0.47 |

|

M48

|

1.89 | 3.39 | 2.36 | 0.47 |

|

M56

|

2.21 | 3.78 | 2.76 | 0.47 |

|

M64

|

2.52 | 4.77 | 3.39 | 0.55 |

|

M76

|

2.99 | 6.03 | 3.94 | 0.59 |

|

M90

|

3.70 | 6.82 | 4.73 | 0.79 |

|

M100

|

4.29 | 7.21 | 5.52 | 0.79 |

Note:

- Material – raw or galvanized carbon steel, or stainless steel.

- Custom pin sets are available upon request.

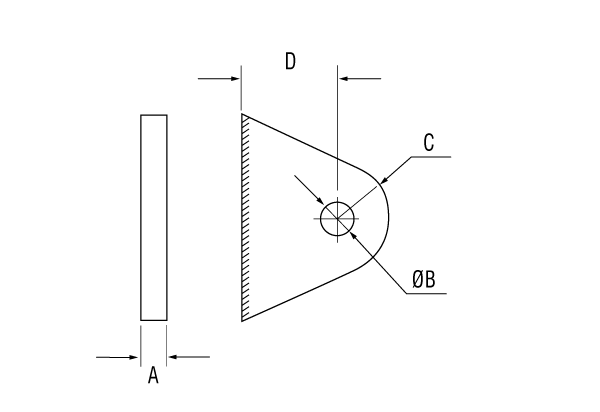

Connection Plate

|

Matching Rod Size |

A | B | C | D | Plate Grade |

|

Thread |

in. | in. | in. | in. | |

|

M12

|

0.39 | 0.51 | 0.83 | 1.26 | S355 |

|

M16

|

0.47 | 0.67 | 1.06 | 1.50 | S355 |

|

M20

|

0.59 | 0.83 | 1.30 | 2.05 | S355 |

|

M24

|

0.79 | 0.99 | 1.62 | 2.44 | S355 |

|

M30

|

0.99 | 1.22 | 2.05 | 2.92 | S355 |

|

M36

|

1.18 | 1.46 | 2.40 | 3.43 | S355 |

|

M42

|

1.38 | 1.69 | 2.72 | 3.82 | S355 |

|

M48

|

1.58 | 1.93 | 3.07 | 4.22 | S355 |

|

M56

|

1.77 | 2.25 | 3.78 | 4.93 | S355 |

|

M64

|

2.17 | 2.56 | 4.33 | 5.52 | S355 |

|

M76

|

2.76 | 3.07 | 5.16 | 6.34 | S355 |

|

M90

|

3.15 | 3.78 | 6.34 | 7.72 | S355 |

|

M100

|

3.35 | 4.37 | 7.41 | 8.75 | S355 |

Note:

- All structural plate grades to BS EN 10025 (Carbon Steel) or BS EN 10088 (Stainless Steel).

- Custom connection plates are available upon request.

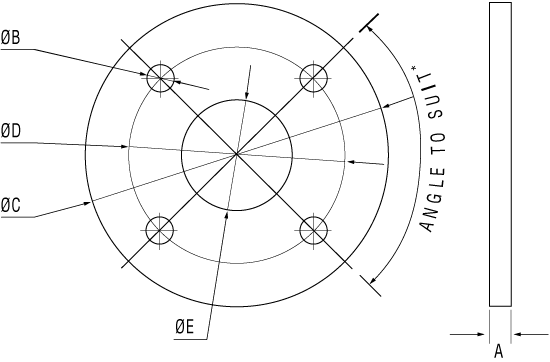

Centre Discs – Carbon Steel or Stainless Steel

|

MATCHING ROD |

A | B | C | D | (Optional) E |

|

THREAD |

in. | in. | in. | in. | in. |

|

M12

|

0.394 | 0.512 | 5.709 | 4.331 | 1.969 |

|

M16

|

0.472 | 0.669 | 7.283 | 5.512 | 2.362 |

|

M20

|

0.591 | 0.827 | 9.646 | 7.087 | 2.756 |

|

M24

|

0.787 | 0.984 | 11.220 | 8.268 | 3.543 |

|

M30

|

0.984 | 1.220 | 13.780 | 10.236 | 3.937 |

|

M36

|

1.181 | 1.457 | 16.535 | 12.205 | 4.724 |

|

M42

|

1.378 | 1.693 | 19.291 | 14.173 | 5.512 |

|

M48

|

1.575 | 1.929 | 22.047 | 16.142 | 6.299 |

|

M56

|

1.772 | 2.244 | 25.984 | 18.898 | 7.874 |

Note:

- Centre disk designs are based on grade S355J2G3 plate to BS EN 10025 for carbon steel or BS EN 10088 for Stainless Steel.

- Local plate equivalents may be used, but must match associated ARS rod or compression strut system mechanical properties.

- Ensure adequate clearances for for paint or galvanising thickness to match fork ends.

- Suits ARS2, ARS4 and ARS6 systems. ARS1 and ARS3 systems upon request.